Research & Design at Hilton & Moss

Precision Engineering for Classic and Performance Cars

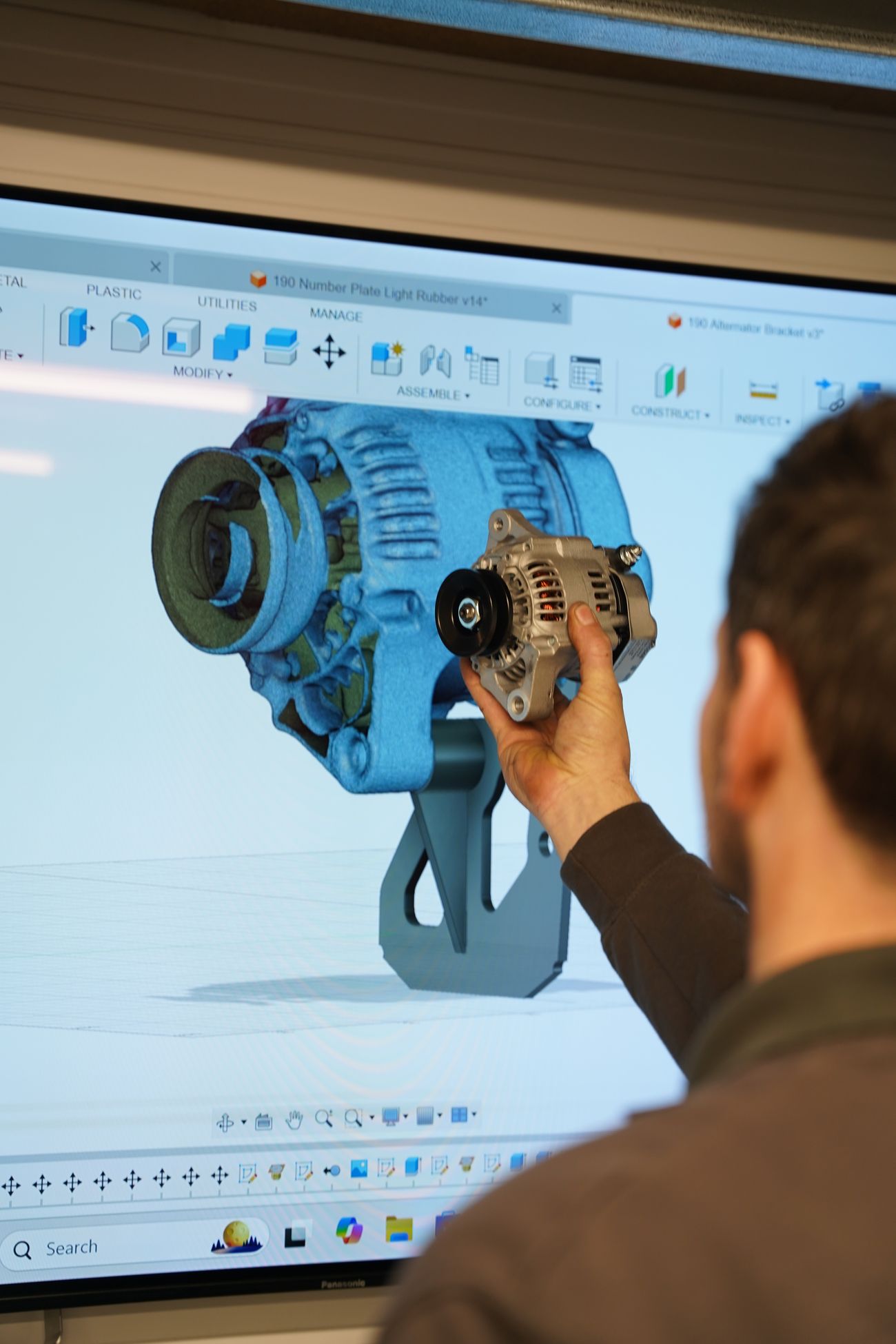

At Hilton & Moss, our in-house Research & Design department blends traditional craftsmanship with cutting-edge technology to support the preservation and enhancement of classic and performance vehicles. Whether you're restoring a rare component or developing a bespoke upgrade, our R&D services allow us to approach every project with unmatched accuracy and attention to detail.

Reverse Engineering & CAD Modelling

We’re proud to offer the ability to 3D scan genuine parts and create highly accurate digital models using CAD (Computer-Aided Design). This allows us to digitalise and catalogue original parts for remanufacture or reengineer parts as required to enhance or evolve their operation. Whether a part is no longer available or needs reengineering our team can develop a solution based on your needs.

This process is particularly valuable for heritage vehicles, where sourcing original parts can be difficult or impossible. With our expertise, we ensure these vehicles can continue to perform and be enjoyed as intended.

3D printing and moulding

As part of the next stage in automotive restoration and innovation, we have invested in advanced 3D printing technologies to complement our scanning and design work. This is a highly efficient solution for problem-solving both motorsports vehicles and road-going cars. 3D printing allows us to produce prototype parts quickly, test fitments, and even create final-use components where appropriate.

Beyond prototypes and small-batch production, 3D printing also enables us to create precise moulds for casting and manufacturing more complex or traditional components. Whether it’s for metal casting, plastic injection, or composite layups, these moulds are designed in-house and produced with the same attention to detail as the original parts, ensuring accuracy, repeatability, and exceptional quality in the final product.